Compare MicroSeal to Other Common FiberProtectors.

The Choice is Clear.

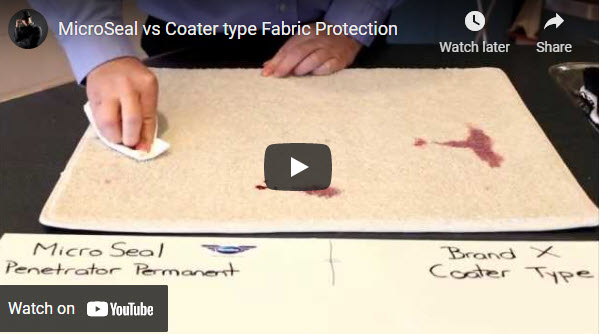

THE BEAD TEST COMPARISON

Don’t be fooled. Sometimes a simple bead test of a coater (fluorochemical or polymer based fabric protectors) vs. MicroSeal will result in the “apparent superiority of the coater type protectant. This is because the coater will cover more of the space between the fibers while MicroSeal Protectant actually penetrates and seals the individual fibers. Additional testing after cleaning and wear results in the coater breaking up leading to permanent stains on the fibers afterwards.

Even ordinary dirt can be difficult to vacuum because the broken coater material “clings to” the dirt. MicroSeal does not break up, wear off, or clean off and continues to protect fibers from sun fading and permanent stains for several years.

Don’t be fooled by competitors who have suddenly started marketing their product as “nano-technology”, “permanent” or “long lasting” in response to MicroSeal’s performance. If their product is a fluroochemical or polymer, it is a coater that will fracture and clean or wear off easily and will need to be reapplied after each cleaning. This type of poor product performance combined with the EPA’s 2010/2015 PFOA Stewardship Program (a heavy verdict against the flurochemical industry) makes the choice clear.

MicroSeal will always win the most important test of all…THE TEST OF TIME. More than words, 25 years in the aerospace industry, and worldwide independent laboratory testing speaks for itself.

Common Fiber Protectors

Penetrates complete fiber and will survive many professional cleanings and normal wear

Does not penetrate fiber, but coats only where spray hits. Cleaning or normal wear easily fractures the fiber protection and you must pay for re-application

Reduces sunfading by nearly 100% on most fabrics – Independent laboratory verification

No protection against sunfading. If they make the claim, no independent laboratory verification

MicroSeal has been thoroughly tested by independent laboratories from around the world

No independent laboratory tests

Reduces smoke density

No protection. In fact, most fiber protectors are highly toxic when they burn

Reduces flame spread

No claims of reducing flame spread

If flame retardant is applied to fabrics, retardant is sealed in so normal everyday cleaning won’t remove

No protection for flame retardant

Colorfast-has no effect on color or texture of treated fabrics

Have been known to “yellow” light colored fabrics over time or when sprayed

Mildew and static electricity resistance

No protection

MicroSeal only attaches to fibers and will not seal in anything non-fibrous, so fabric / carpet does not have to be clean before application

Many products will seal both fibrous and non-fibrous particles. Therefore, dirty fabrics treated with these chemicals will have dirt, stains, etc., sealed in at time of treatment.

Does not damage woodwork, metal

paint or glass. Safe and easy to use

Will spot woodwork, metal and glass. Can cause problems if not removed quickly

Can be used on any material with a fibrous nature including suedes and smooth finished leathers

Cannot be used on some types of fabrics, such as suede or smooth finished leathers

MicroSeal is non-toxic and non-allergenic – Carrier has a EPA rating of GRAS (Generally

Recognized As Safe)

EPA test reports have cited health and environmental concerns with fiber protectors that use flurochemicals and PTFE Resin – 95% of fabric protectors are either fluorochemical or co-polymer / polymer (plastic) based

Contact us today to schedule your appointment to protect your valuable textiles with MicroSeal Protector.